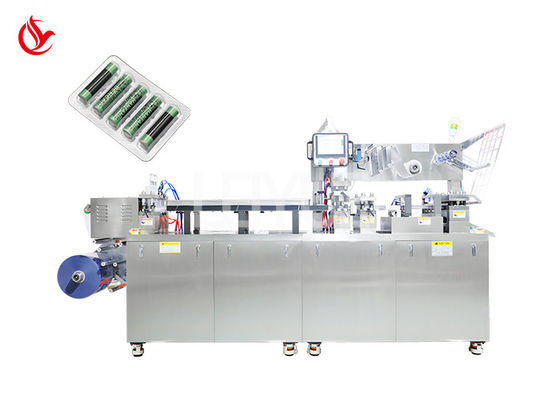

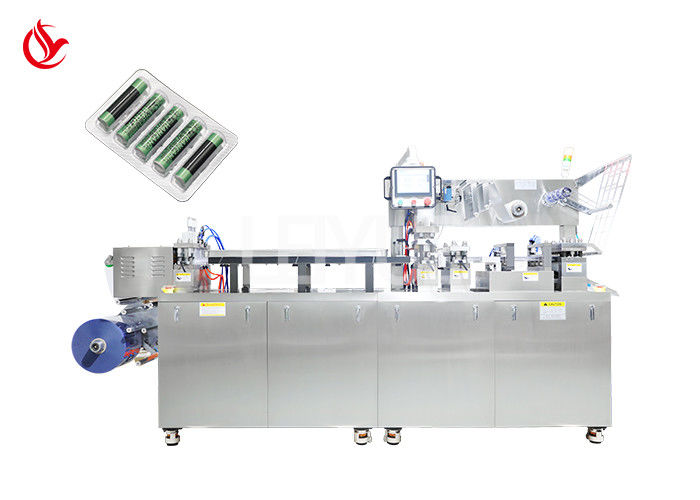

OEM Automatic Blister Blister Forming Machine For Cigarette Filter Packaging

Product Details:

| Place of Origin: | Shenzhen China |

| Brand Name: | LEIYUE |

| Certification: | CE |

| Model Number: | DPP-260 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | USD22000-27000/unit |

| Packaging Details: | Wooden box |

| Delivery Time: | 25-30 work days |

| Payment Terms: | T/T |

| Supply Ability: | 20 units per month |

|

Detail Information |

|||

| Cutting Frequency: | 10-32times/min | Max Shaping Areas And Depth: | 240*140*26mm |

|---|---|---|---|

| Air Pressure: | 0.4-0.6MPa | Power Supply: | 380V/50Hz 8.5KW |

| Main Motor Power: | 2.2KW | PVC Hard Pieces: | 260*0.3-0.6mm |

| PTP Aluminum Foil: | 260*0.025-0.05mm | Machine Dimensions: | 3500*800*1800mm |

| Net Weight: | 1400kg | ||

| High Light: | OEM blister forming machine,Cigarette Filter blister forming machine,OEM automatic blister forming machine |

||

Product Description

Cigarette filter and blister packaging machine

The cigarette filter blister packaging machine is an automated packaging mechanical equipment specifically used for cigarette filter packaging. Its main working principle is to introduce plastic rolls into the equipment, and then through heating, forming, cutting and other processes, make the plastic into a bubble shaped packaging material suitable for cigarette filter packaging. Finally, the filter and cigarette are combined to form a finished product.

The main advantages of the cigarette filter bubble cover packaging machine include:

1. Efficient automation: The cigarette filter bubble cover packaging machine has the characteristics of efficient automation, which can achieve fast packaging production lines and automatically complete various packaging process flows, thereby improving production efficiency.

2. Multifunctionality: The cigarette filter blister packaging machine can achieve various packaging and sealing methods according to different cigarette sizes and filter length requirements, thereby adapting to different packaging needs.

3. Energy conservation and environmental protection: The cigarette filter and blister packaging machine adopts advanced energy-saving technology and environmentally friendly materials, which can reduce energy consumption and waste production, and has a good protective effect on the environment.

echnical Specifications:

| Model | DPP-260 |

| Cutting frequency | 10-32times/min |

| Capacity |

Specific production capacity depends on the size of the product segment |

| Max shaping areas and depth | 240*140*26mm |

| Air pressure | 0.4-0.6MPa/ ≥0.3m³/min |

| Power supply | 380V/50Hz 8.5KW |

| Main motor power | 2.2KW |

| PVC hard pieces | (width)260*(thickness)0.25-0.5mm |

| PTP aluminum foil | (width)260*(thickness)0.025-0.05mm |

| Dialysis paper | (width)260*50-100g |

| Mould cooling | tap water or recycling water |

| Machine dimensions | 3500*800*1800mm |

| Net weight | 1400kg |

Workflow:

Heating of PVC material→PVC blow molding→Manually placing products→Aluminum foil heat sealing→Finished product punching and cutting

![]()

![]()

![]()

![]()

![]()